Accu-Link®

Overview

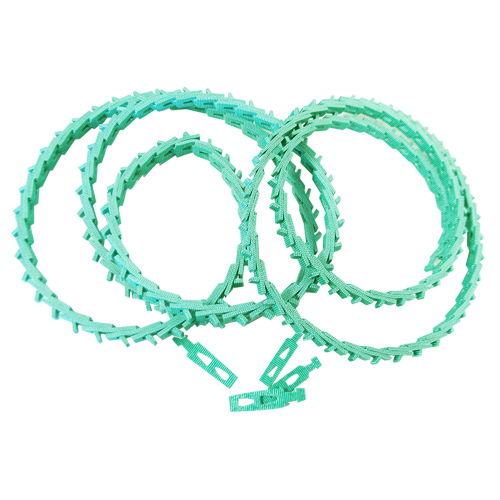

Accu-Link®

The original concept: designed as emergency belts to be used in place of V-belts in case of unexpected failure.

Today Accu-Link® belts find application in many other fields as original equipment, thanks to their performance.

Features

The ideal temporary replacement or permanent substitute for conventional rubber V-Belts, Accu-Link® belts combine superior strength, durability and quick easy assembly to keep equipment up and running at the same running horse power ratings as rubber belts. Furthermore, Accu-Link® belts can have wide length variability simply by modifying the number of links.

Accu-Link® belts are manufactured with a revolutionary new process which creates smooth, precise side profiles on each link. Links are made with a polyurethane polymer reinforced by a multilayer woven polyester fabric.

Main features and advantages:

EASY TO ASSEMBLE

Accu-Link can be assembled without any tool and in a matter of seconds.

EASY TO INSTALL

Accu-Link can be adapted to every length; in case of difficult layout or when taking the drive apart would take too long. Acculink can be installed open and closed afterwards, in a very easy and fast way.

SMALL INVENTORY

With one roll of Accu-Link it is possible to get any length of classical V-belts; with one roll per section, inventories will be much smaller, easier and cheaper to manage.

HIGH POWER RATE

Accu-Link has power ratings similar to classical V-belts.

HIGH RESISTANCE TO ENVIRONMENT

Thanks to its state-of-the-art materials, Accu-Link can withstand to salt, chemicals, mineral pure oils and greases. This increases the life time compared to standard rubber V-belts.

HIGH TEMPERATURE RESISTANCE

Accu-Link can operate un a wide range of temperature:

-25 °C / +80 °C (-13 °F / 176 °F)

HIGH RESISTACE TO HARSH ENVIRONMENT

Accu-Link is suited for harsh environment where it can last ever longer than standard rubber V-belts.

QUIET AND SMOOTH RUNNING

Thanks to the superior finishing.

Main components

Accu-Link® belts are manufactured with a revolutionary new process which creates smooth, precise side profiles on each link. Link are made with a polyurethane polymer reinforced by a multilayer woven polyester fabric.

Mechanical and chemical properties

- Flexibility thanks to the length adjustment, obtainable by modifying the number of links

- Reduce misalignment

- Easy assembly, easy installation (no need to disassemble the pulleys)

- High resistance to harsh environments

- Accu-Link® belt working temperature -25°C / +80°C

Main Applications by Industry

Range

Z/3L, A/4L, B/5L, C.