Chains

Overview

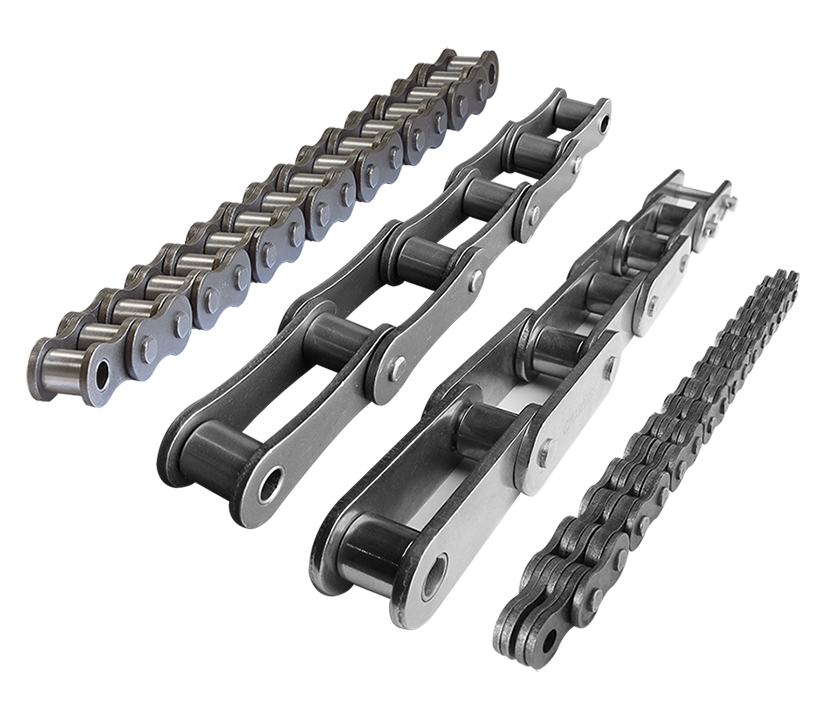

Chains

Challenge’s extensive range of Roller, Leaf, Timber, Agricultural and Conveyor chains not only offer all the manufacturing refinements and life optimising characteristics that today’s engineers and designers expect; they do so without compromise in value or quality.

A full range of attachments are also available as are many types of specially designed chain to suit customer’s specific requirements (e.g., sugar, cement, palm oil, bulk material handling etc).

One of our strongest innovations is our range of both transmission and conveyor chain featuring spin riveted pins.

This makes the Challenge chain range the ideal choice for any new build or replacement application in South Africa.

Features

Challenge offers a large range of various types of chain including – Transmission, Conveyor, Agricultural, Leaf and many types of special chains

Challenge Transmission Roller chain

Challenge roller chain is supplied in five meter boxes including one connecting link. Some sizes are available on reels or in 10ft boxes.

The range includes – ISO, BS, ANSI and many bespoke chains.

ISO roller chain – standard, straight side plate, extended pin, hollow pin, stainless steel, nickel plated, zinc plated, double pitch and specials.

ANSI roller chain – standard, heavy duty, cottered, cottered heavy duty, straight side plate, extended pin, stainless steel, nickel plated, zinc plated, double pitch (including extended pin, hollow pin) and specials.

Roller chain attachments – cover a large range for both ISO and ANSI chain, Timber, Agricultural and Conveyor chain.

Challenge transmission chains have a longer life because:

• Pins – manufactured from case hardened chrome manganese molybdenum steel. This increases wear resistance with more shock absorption ability.

• Pre-stretched – “fit and forget”.

• Ball swaged holes – combats fatigue failure.

• Shot peened rollers and side plates – reduces fatigue failure.

• Deep waisted side plates – increases breaking load and reduces stress.

• Solid rollers – prolongs wear life.