MEGALINEAR FC

Przegląd

MEGALINEAR FC

FC is the acronym for Food Contact

MEGALINEAR FC is the new belt from Megadyne for the food processing industry, made with food contact approved materials according to EU 1935/2004 standard and further update EU 10/2011; NSF/ANSI/3A 14159-3 certification, accepted and approved by USDA (United States Department of Agriculture).

Due to their good chemical resistance and to the certified compounds for humid and dry food contact, this belt is particularly recommended for food processing and packaging applications.

Funkcjonalności

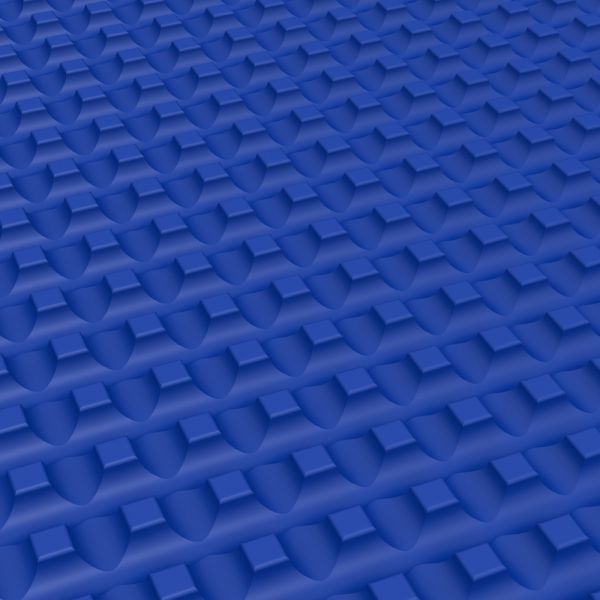

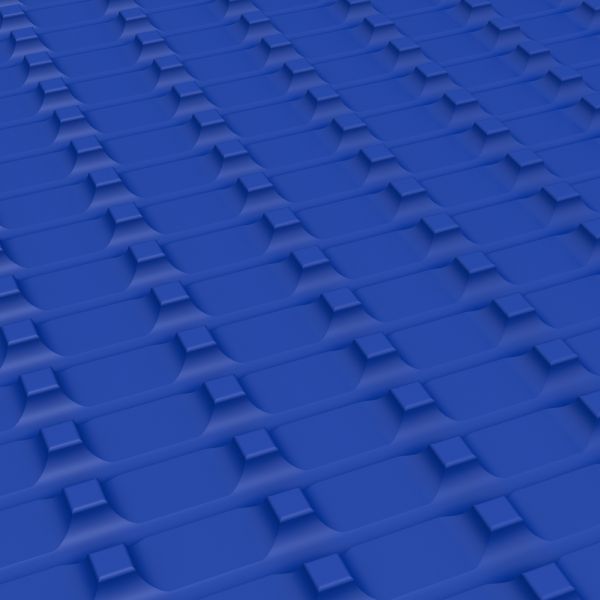

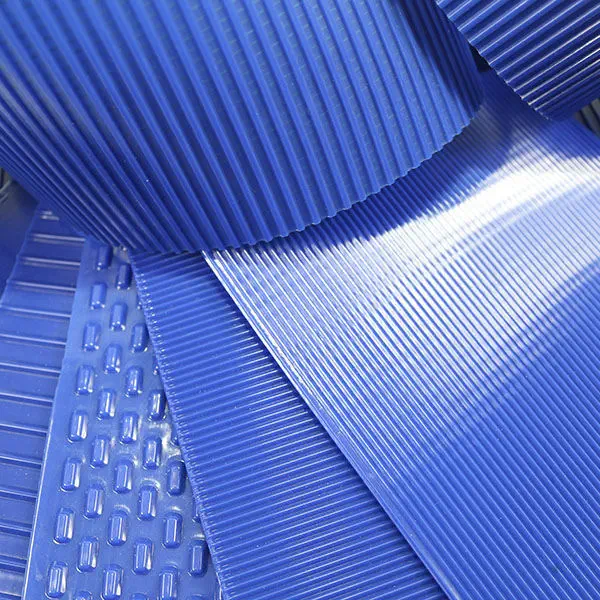

The new MEGALINEAR FC belt matches the power and precision for synchronous conveying (balanced tracking, low running tension and low vibration) meeting the criteria where food contact is required: MAXIMUM RELIABILITY, TOTAL HYGIENE. It is manufactured in T5/T10 pitch without a gap between the teeth and is available with a variety of backing profiles, for all kinds of conveying and processing applications.

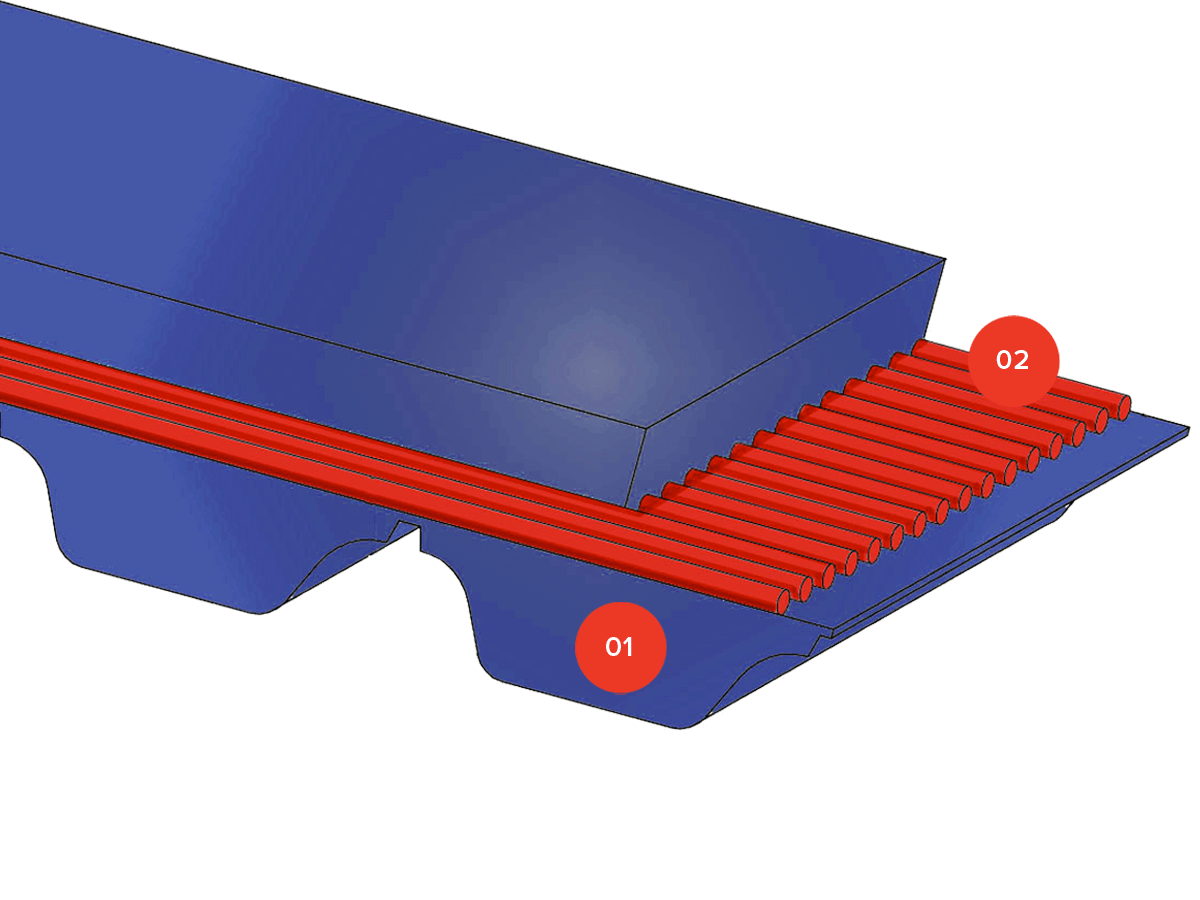

Główne elementy

01 / BODY

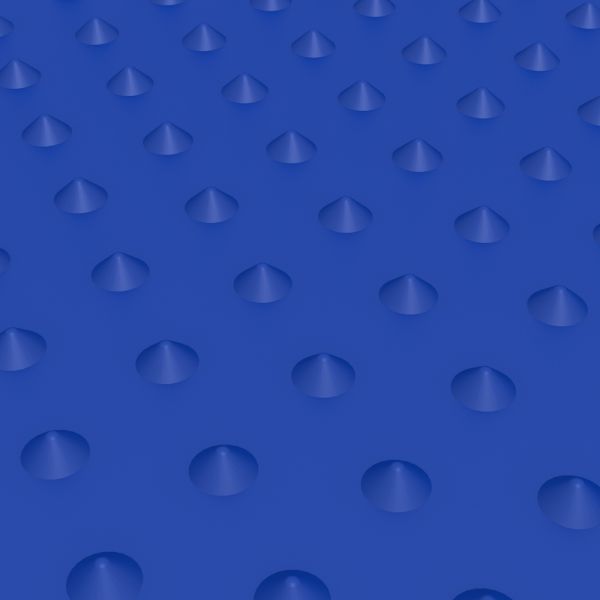

The body of the belt is dark blue thermoset polyurethane 85 ShA.; no gap between teeth on drive side.

02 / CORD

The cord is in Kevlar: max. 50 cords in a 150 mm wide product.

Właściwości techniczno-mechaniczne

Characteristics:

- Special detectable dark blue polyurethane compound.

- Standard cords: S and Z torsion Kevlar for Megalinear FC; Stainless steel for Megaflex FCM and Megalinear FCM.

- Standard splice method by finger splice.

- Manufactured in T5/T10 pitch without a gap between the teeth and available with a variety of backing profiles.

- Customizable with cleats, made of the same detectable thermoplastic compound and applied by welding.

- No risk of slippage, even in greasy and humid environments.

- Zero risk of fraying and detaching of back profile.

- Used even at the smallest bending diameter, with small drive pulleys.

- MEGALINEAR FC belt working temperature -25°C/+80°C.